Metal folding service

Our work has evolved over time, adapting to the growing demand for these products. So we have a qualified and modern equipment, we are ready for the new times in the industry, we always work with quality materials.

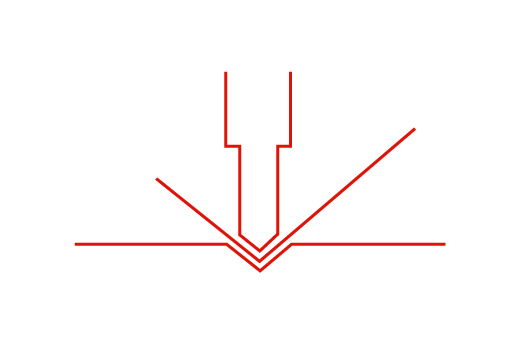

What is the folding of materials?

- It is the process used to shape metal parts without cutting, separating or weld the metal by a machine that achieves the desired dimensions and shapes.

- The most common processes are bent rod, tube bending, bending and folding sheet metal.

- Hidegar Laser have folding machines of different sizes and powers that allow work both large tonnage and small areas that require greater accuracy.

It's fast, productive and profitable

Laser is synonymous with quality and precision, able to perform work where other cutting systems can not reach.

For materials such as aluminum, stainless steel, etc. thickness up to 15mm, cutting is faster than other cutting methods.

For materials such as aluminum, stainless steel, etc. thickness up to 15mm, cutting is faster than other cutting methods.

Higher quality cuts and cutting surface cleaner

No contact between tool and workpiece, and the possibility of buckling or bending of the material or of faults, occurring tear and wear is reduced because the laser systems have very little affected by the heat with respect to other thermal cut area.

Generates no impurities and has multiple applications

As thermal nature, since no chip generates material removal is effected by melting and vaporization.

Generate complex cuts and permanently recorded that is not erased by time and have excellent quality and precision.

Generate complex cuts and permanently recorded that is not erased by time and have excellent quality and precision.