Plasma cutting service

In the field of metallurgy, specifically in the activity of cutting metal parts laser, the market demands a millimeter and perfect finish. The tradition has given way to the more precise technology. The customer knows what you want and why choose us.

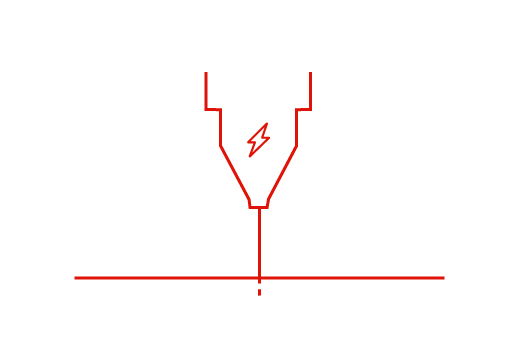

What is plasma cutting?

- This is a process that uses gas and an electrical arc for cutting steel and other metals of different thicknesses.

- During a plasma gas ejected at high speed through a nozzle along a concentrated arc allows the metal to pass the fourth state of matter, plasma, which achieves and melt metal is used to make a cut. Unlike the flame cutting, plasma cutting has a greater range of application.

- In Hidegar want to highlight the versatility of plasma cutting to cut any conductive metal material even much thinner gauges and a high cutting speeds (depending on the thickness of the piece, it is up to 5 or 7 times higher than flame cutting) offering higher productivity obtaining optimum results.

- Factors such as the reliability of the machine and cut quality are essential to ensure the needs in the cutting process.

Versatility

Generate very complex cuts in major parts to oxyfuel.

Quality results

The possibility of buckling or bending is reduced in the absence of direct contact with the workpiece

We care about the environment

Material by melting and vaporization is removed and does not generate impurities