Laser cutting service

In the field of metallurgy, specifically in the activity of cutting metal parts laser, the market demands a millimeter and perfect finish. The tradition has given way to the more precise technology. The customer knows what you want and why choose us.

What is laser cutting?

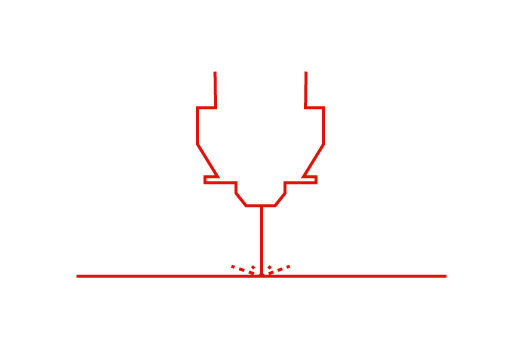

- This is a technology in which a light beam is directed from the output of an optical resonator to the feedstock. This powerful beam becomes a great source of energy that causes the material to melt and burn through a gas jet.

- During cutting, the optical path length of the laser beam is changing forming what is known as “flying optics”.

- Depending on the type of material the oxygen gas or nitrogen gas is used.

- Allows jobs where other cutting systems can not reach. Laser energy allows the use in industrial material processing applications such as flat sheets or cut tube-shaped materials or other structures.

Fast, productive and profitable

For metallic materials thicknesses up to 15mm, cutting is faster than other methods.

High quality cuts

This system reduces the possibility of failure, tear and wear occur.

We care about the environment

Chip is not generated because the material removal is effected by melting and vaporization.